CAPABILITIES

Natural gas compressor hookup site.

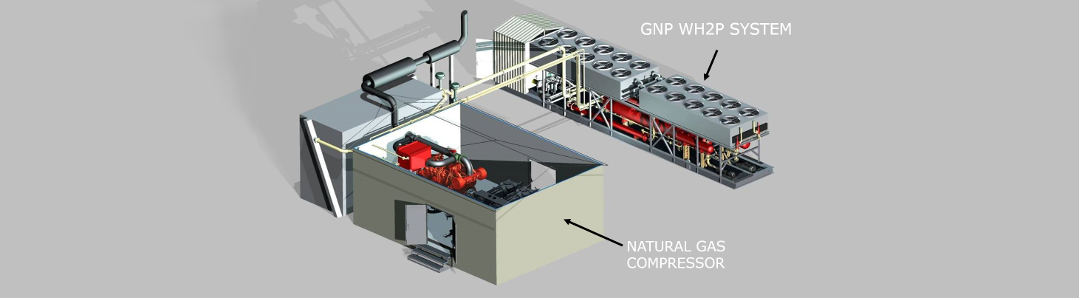

Natural gas compressor hookup site. 3D rendering of GNP's waste heat to power system

3D rendering of GNP's waste heat to power system GNP's waste heat to power system installed at compressor site.

GNP's waste heat to power system installed at compressor site. Construction of GNP's waste heat to power system

Construction of GNP's waste heat to power system Installation of GNP's waste heat to power system

Installation of GNP's waste heat to power system Installation of GNP's waste heat to power system.

Installation of GNP's waste heat to power system.

GNP In-house Capabilities

GNP has developed extensive knowledge and experience in developing its systems. Specifically, GNP has developed the following in-house skills:

- Developed extensive processes to:

- Guide the project development process,

- Contract manufacture with 3rd party fabricators,

- Complete all regulatory application processes in a timely manner, and

- Develop and utilize an ERP System to facilitate project execution.

- Initiated regulatory changes (provincially and federally) to pave the way for waste heat to power projects.

- Developed control system software in-house. Field tested and proved start-up/control logic for the unit.

- Documented extensive business processes, fabrication and installation documents to support 3rd party fabrication and field construction. This documentation was the origin of our ERP system which allows GNP to deliver on multi-unit projects in a short period of time.

- Hands-on, in-house experience with system engineering: process simulations, equipment specifications, design, fabrication packages, permit applications, remote communication and control system, and commissioning.

- Developed strong supplier/vendor/fabricator network including multiple contingency suppliers, as well as a network of external technical and commercial consultants